How it Works

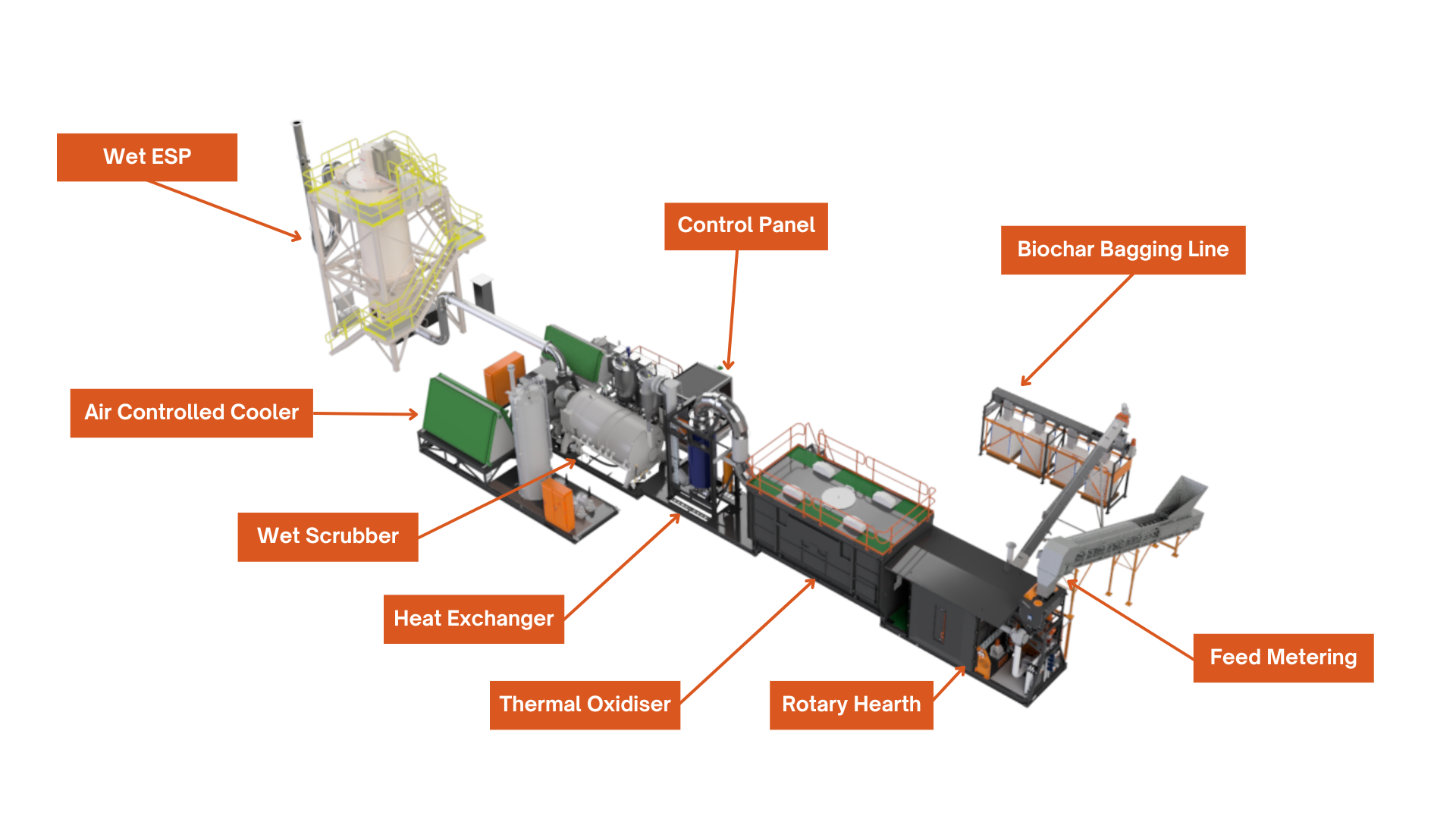

The core component of the Pyrocal CCT system is the hearth, which is a modified updraft gasifier that is fitted with our proprietary high temperature components and controls.

Feedstock is continuously metered into the top chamber of the hearth where it rapidly heats, dries and commences to pyrolyse (thermally decompose). A small fraction of the volatile components released from the feedstock are mixed with a controlled amount of air and ignite. Partial combustion of volatile components in the hearth provides the heat that makes the process autothermal.

The off-gases travel up through the hearth to the thermal oxidiser, where they are mixed with more air and oxidised completely through to water and carbon dioxide. The feedstock is then transported through a number of chambers before dropping out into a screw conveyor where it is quenched and discharged as biochar.

The temperature and oxygen profiles in the hearth are controlled to achieve the desired biochar yield and quality. Temperatures in the hearth range from 500 to 750 degrees C.

The thermal oxidiser is controlled to a selected temperature in the range between 850 to 1100 degrees C according to the nature of the biomass and the emissions control requirements. Oxygen is monitored and controlled to achieve complete oxidation of the combustible gases. Downstream, a heat recovery system and emissions controls (venturi/wet scrubber/ESP) can be included into the system.

The system is controlled by a PLC which can be operated from a local or remote mounted HMI/SCADA.

Key Technical Features

The mechanical moving bed provides flexibility for a wide range of feedstocks.

Direct heat transfer to the incoming biomass.

Controlled temperatures in each stage of the hearth and thermal oxidiser optimize biochar quality and emissions control.

Controlled two-stage oxidation of the released volatile matter provides efficient control of air pollutants.

Operation of the system under negative pressure eliminates flammable gas leaks.

Fully autothermal operation (i.e. after startup no other fuel sources are required).

Rapid start-up. Typically, cold to full throughput in 60-90 minutes. The high quality construction materials allow heating from cold to full operating temperature without damage.